Welcome To CARHOME

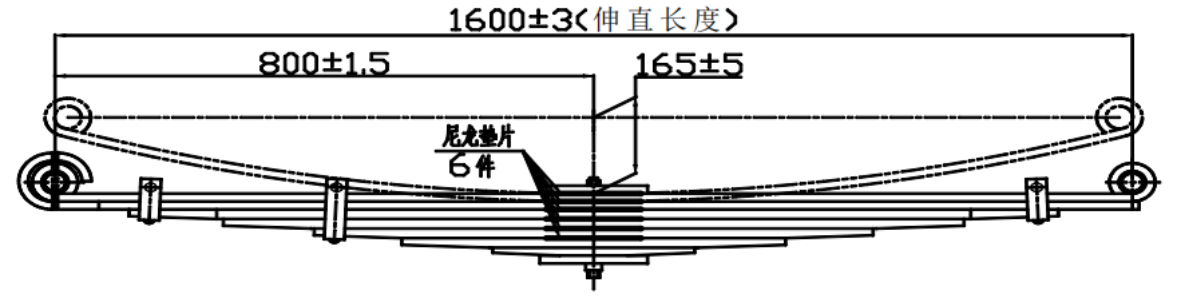

1-51130-961-0 Heavy Duty Leaf Spring for ISUZU Truck

Detail

The leaf spring is suitable for ISUZU heavy duty truck

1. The item total has 8 pcs, the raw material size is 80*14 and 80*17

2. Raw material is SUP9

3. The free arch is 165±6mm, the development length is 1600, the centre hole is 16.5

4. The painting use electrophoretic painting

5. We also can produce base on client's drawings to design

What is the difference between light and heavy duty leaf springs?

The difference between light and heavy leaf springs is the amount of weight they can withstand.

Heavy leaf springs, as the name suggests, are designed to carry heavier loads than light leaf springs.

In turn, they are usually found on larger, HGVs (Heavy Goods Vehicles) like lorries which – with the right equipment – can withstand up to 44 tonnes.

Alternatively, light or standard leaf springs are typically installed on LCVs (Light Commercial Vehicles) like vans, which can withstand up to 3.5 tonnes.

Are there different types of leaf springs?

Yes, there are two main types of leaf springs: mono leaf springs and multi leaf springs.

Mono leaf springs feature a single layer of metal without any additional plates, whilst multi leaf springs feature multiple metal plates fixed together to create a stack.

Whilst both vehicle support vehicle suspension systems, multi leaf springs are more popular amongst commercial vehicles as they offer greater strength and durability.

Applications

What are the benefits of leaf spring suspension?

There are several benefits to using a leaf spring suspension system, some of which include:

Durability – due to their layered design, leaf springs are incredibly long-lasting and can comfortably withstand heavy loads for hundreds of thousands of miles.

Versatility – leaf springs can be modified and designed to meet manufacturers specifications for a wide variety of vehicles including vans, trucks, trailers and lorries.

Cost-efficiency – with their simple yet effective design, leaf springs are incredibly cost-effective as they are reliable and relatively easy to

Comfort – leaf springs ensure a smooth ride when transporting heavy loads – even when encountering uneven roads and potholes.

Safety – leaf springs optimise your vehicles performance by ensuring your tyres are aligned, your vehicle is at an even height and steering is unimpaired.

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

Packing & Shipping

QC equipments

Our advantage

Quality aspect:

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、Research and development: Investing in R&D enables the factory to continuously improve its products and develop innovative leaf spring designs.

2、Compatibility with international standards: The leaf springs are engineered to comply with global safety and quality regulations.

3、Production capacity: Our factory's large-scale production capabilities ensure a steady supply of leaf springs to meet our customer’ demands.

4、Metal treatment technology: Utilizing heat treatment and surface finishing processes strengthens the leaf springs and protects them from corrosion.

5、Sustainable practices: The factory may prioritize eco-friendly manufacturing methods and materials in line with environmental regulations.

Service aspect

1、With over 22 years of experience

2、Our team specializes in supplying, fitting and repairing commercial leaf springs

3、Stocking a wide variety of makes and models for professionals and the public

4、We only offer the highest quality products and services for your vehicles

5、Our customers are important to our business, we offer all new and existing customers a 12 month guarantee on standard parts along with next day delivery