Welcome To CARHOME

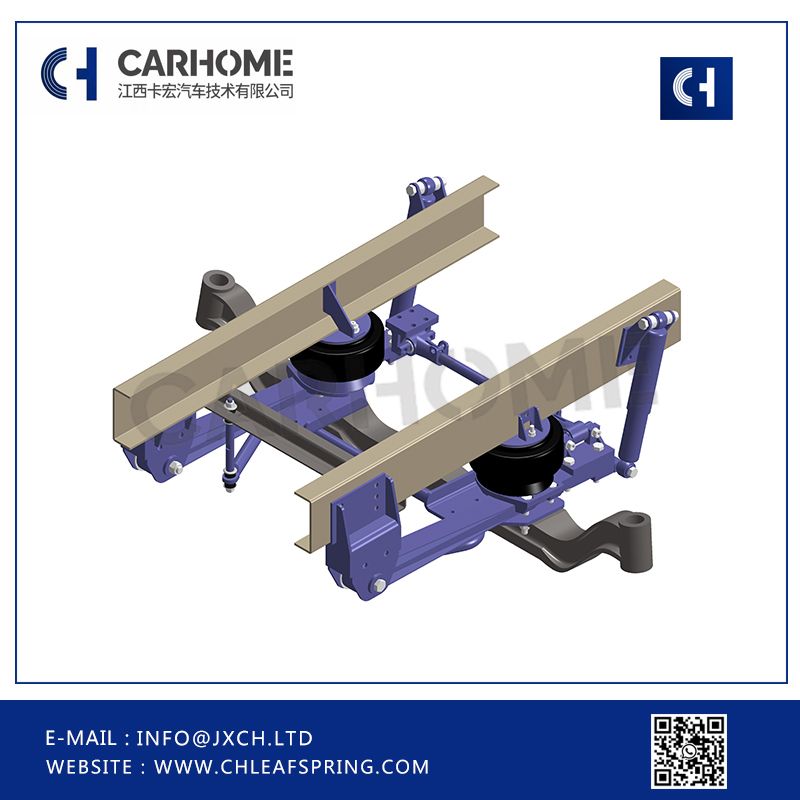

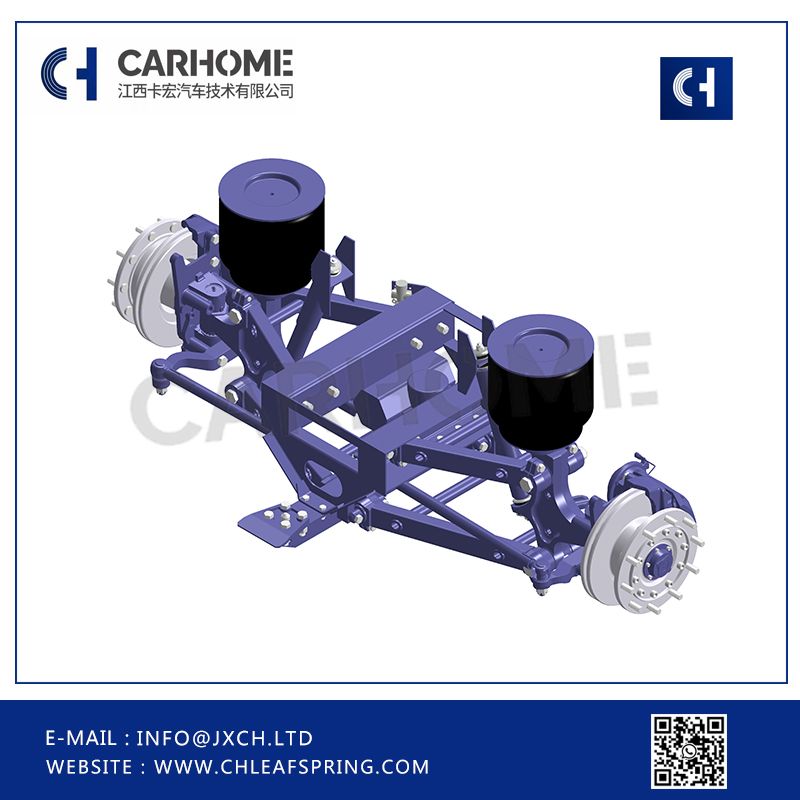

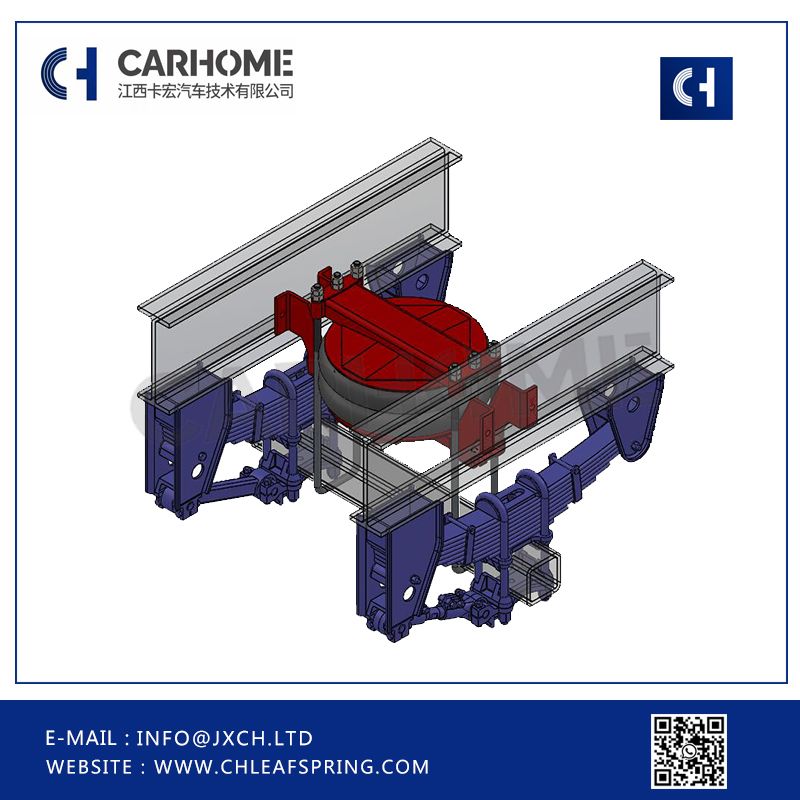

11T 13T Air Suspension for Semi Trailers and Trucks with Air Bags

Detail

| Types | German series suspensions, American series suspensions, bogie/boogie suspension series, air suspension series, rigid suspension series, YORK suspensions, ROR suspensions, HENRED suspensions, semi-trailer suspensions, trailer suspensions and agricultural series, etc. |

||||

| Valvel | WABCO, SORL | ||||

| Air Bag | Firestone,Continental, Sampa, Domestic | ||||

| Brand | BPW suspensions, FUWA suspension, YORK suspensions, ROR suspensions, HENRED suspensions. | ||||

| Components | Front hangers, rear hangers, center hangers, equalizers, equalizer pins, equalizer bushes, brackets, axle seats, axises, bushes, leaf springs, U-bolts, bolts, fixed arms, adjustable arms, hanger spacers, reinforcing plates, reinforcing brackets for equalizers, etc. |

||||

| Colors | Black, Grey, Red | ||||

| Package | Carton box | ||||

| Payment | TT, L/C | ||||

| Lead Time | 15~25 working days | ||||

| MOQ | 1 Complete | ||||

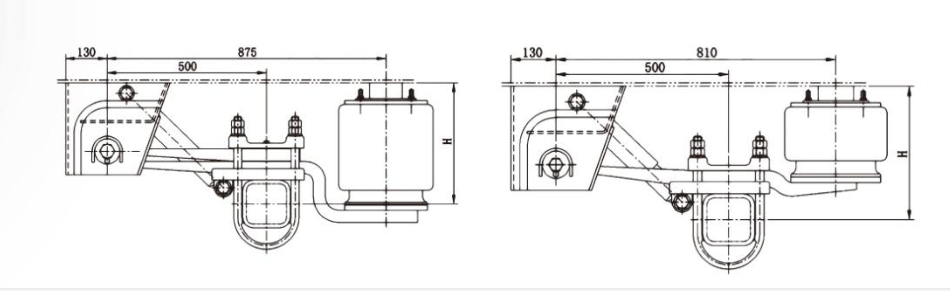

| No. | H | Offset Distance | Axle Spacing | Air Bag Spec | Axle Load |

| (mm) | (mm) | (mm) | (mm) | (kg) | |

| 1 | 380 | 90 | 1220-1360 | ∅360 | 10000 |

| 2 | 430 | 90 | 1220-1360 | ∅360 | 12000 |

| 3 | 480 | 90 | 1220-1360 | ∅360 | 12000 |

| 4 | 380 | 90 | 1220-1360 | ∅360 | 13000 |

| 5 | 430 | 90 | 1220-1360 | ∅360 | 13000 |

| 6 | 480 | 90 | 1220-1360 | ∅360 | 13000 |

Applications

Air suspension is used in place of conventional steel springs in heavy vehicle applications such as buses and trucks, and in some passenger cars.

It is widely used on semi trailers and trains (primarily passenger trains).

The purpose of air suspension is to provide a smooth, constant ride quality, but in some cases is used for sports suspension.

Modern electronically controlled systems in automobiles and light trucks almost always feature self-leveling along with raising and lowering functions.

Although traditionally called air bags or air bellows, the correct term is air spring (although these terms are also used to describe just the rubber bellows element with its end plates).

The system comprises

1. a vulcanised rubber air spring at each wheel

2. an air compressor, which is typically located in the trunk (boot) or under the bonnet

3. a compressed air storage tank may be included for rapid "kneel", storing air at ~150psi (1000 kPa), note (1psi=6.89kPa)

4. a valve block which routes air from the storage tank to the four air springs via a series of solenoids, valves and many o-rings

5. an ECAS computer which communicates with the car's main computer the BeCM and decides where to route air pressure

6. a series of 6 mm air pipes which channel air throughout the system (mainly from the storage tank to the air springs via the valve block)

7. an air drier canister containing desiccant

8. height sensors ideally on all 4 vehicle corners based, typically, on resistive contact sensing to give an absolute height reference for each corner of the vehicle.

Reference

Production

Packing & Shipping

QC equipments

Our advantage

Characteristics & some benefits of air spring

When the vehicle is not loaded, they are soft, but as the load is raised, the stiffness improves by increasing the air pressure inside the chamber. As a result, when the vehicle is lightly loaded or completely loaded, it provides the best ride comfort. Whenever the load varies, the air pressure is varied to keep the vehicle’s height constant. By absorbing road shock, air springs improve vehicle stability. Air spring systems are made to increase load-carrying capacity, stability, and overall ride quality.