Welcome To CARHOME

Conventional Heavy Duty Suspension Leaf Springs for Semi Trailers

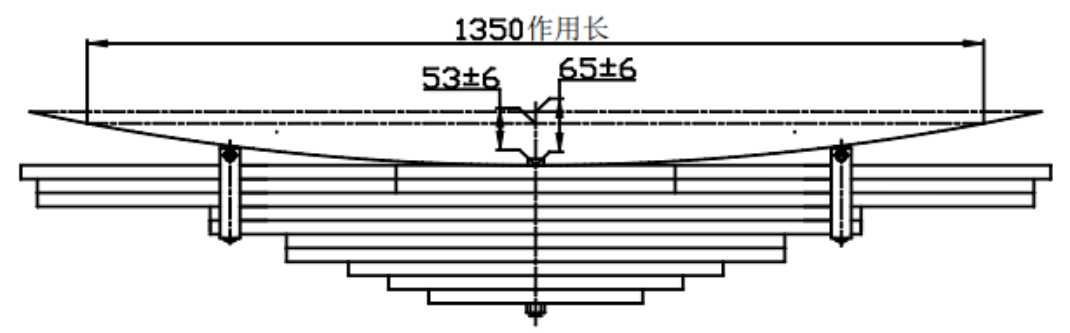

Detail

The leaf spring is suitable for semi-trailer

● The item total has 11 pcs, the raw material size is 90*20 for all leaf

● Raw material is SUP9

● The free arch is 65±6mm, the development length is 1350, the centre hole is 16.5

● The painting use electrophoretic painting

● We also can produce base on client's drawings to design

Hot selling leaf springs OEM numbers:

| S/N | OEM No. | S/N | OEM No. | S/N | OEM No. |

| 1 | SH63-1430-FA | 21 | 48210-87C14-RA | 41 | 621 320 0002 RA |

| 2 | 55020-1T400-HA | 22 | 48150-1890A-FA | 42 | 48210-2341 |

| 3 | MC031096-HA | 23 | 48210-830T0-RA | 43 | 51310-7800-RA |

| 4 | 54010-01Z17-FA | 24 | 8-94343-130-0-RA | 44 | 54010-Z3007-FA |

| 5 | 48120-5380B-FA | 25 | 8-94343-082-M-FA | 45 | 48110-5570A-FA |

| 6 | 1-51110-051M-FA | 26 | MK310031-FA | 46 | 101199SC-RA |

| 7 | 1377695-RA | 27 | 48110-87334-FA | 47 | 48120-4340-FA |

| 8 | 257888-FA | 28 | TYT 48210-OK020HD | 48 | 1-51340-010-0-HA |

| 9 | 29FDZ1-02010 FA | 29 | 8-97092-449 FA | 49 | 0178-01-TA |

| 10 | 352525 | 30 | 48110-3V700-FA | 50 | 54010-Z2006A-FA |

| 11 | CW53-02Z61HD-FA | 31 | 8-97092-445-1-FA | 51 | 48110-8780A-FA |

| 12 | 48220-3430-HA | 32 | 8-94118-505-1-HA | 52 | 54011-99117-FA |

| 13 | 55020-Z9001-HA | 33 | 8-97073-224-M-HA (5L) | 53 | 48150-2341A-FA |

| 14 | 55020-Z3001-RA | 34 | 97073-225M-HA (9L) | 54 | 48150-2341A-FA-HD |

| 15 | 624 320 0006 RA 16L | 35 | 8-97073-224M-RA | 55 | 55020-Z0073A-RA |

| 16 | 54010-G5500MH-FA-HD | 36 | 48110-60391W-FA | 56 | 257624M-R1 |

| 17 | 1915-90-30-41 | 37 | MB294032-FA | 57 | 54010-01Z17-F3H |

| 18 | MK 382877R | 38 | 54010 31Z61-FA | 58 | 54010-NB100-F3 |

| 19 | 48110-87338A-FA | 39 | 352-320-1302-FA | 59 | MK306251-R1 |

| 20 | 48210-87C37A-RA | 40 | 48110-3V790-FA | 60 | 911B-0508-R1 |

Applications

Leaf springs are typically the most important part of a truck or SUV suspension. They are the backbone of your vehicles support, providing load capacity and impacting your ride quality. A broken leaf spring can cause your vehicle to lean or sag, and is strongly recommended to purchase replacement leaf springs. You can also add a leaf to existing springs to increase load capacity. Also available are heavy duty or hd leaf springs for heavy use or commercial applications to increase towing or hauling capacity. When the original leaf springs on your truck, van or SUV begin to fail you will see a visual difference which we call squatting (when your vehicle sits lower in the rear than the front of the vehicle). This condition will affect the control of your vehicle which will cause over steering. CARHOME Springs offers original replacement leaf springs to bring your truck, van or SUV back to stock height. We also offer a heavy duty leaf spring version for your vehicle to give it extra weight capacity and height. Whether you choose an CARHOME Springs' original replacement leaf spring or heavy duty leaf spring you will see and feel an improvement in your vehicle. When refreshing or adding extra capacity leaf springs to your vehicle; remember to also check the condition of all the components and bolts on your suspension. Leaf springs are the most cost efficient suspension solutions for commercial vehicles. Despite of the fact that the history of leaf springs started more than 100 years ago, we can find leaf springs in the latest modern commercial vehicles. Leaf springs on commercial vehicles are not standardised parts therefore each vehicle manufacturer develops own solutions and on one vehicle platform several different variants are used. The results of this is a huge number of article numbers on the market. From technical point of view, leaf springs have three main types.

Multi leaf springs (often said: conventional leaf springs) are the oldest type of leaf spring. They are made from spring leaves with constant cross sections. They are used mainly in construction vehicles, agricultural vehicles and even on rear axles of modern pick ups. Advantages of multi leaf spring are the robustness and cheap repair possibility. In most of the cases no additional stabiliser is needed.

Advantages

1、Simple and robust solution to carry heavy load

2、Cheapest solution for heavy duty commercial vehicles

3、It is not just a suspension element but a robust linkage between the axle and frame

4、It can take not only vertical load but also transversal forces

5、No need for additional stabiliser bar in many cases

6、In comparison to coil springs, leaf spring works under the frame and loading surface can be flat

7、It controls axle damp

8、Maintenance free

9、Easy repair (quick fix) possibility especially in case of multi leaf springs

10、The vehicle can continue the journey, if one of the spring leaves is broken in the spring pack

Disadvantages

1、Heavy system

2、Poor driving comfort (when unloaded)

3、Linear spring characteristics

4、Due to production process no proper corrosion protection is possible (or too expensive)

5、Micro cracks, inclusions can remain in leaf spring material after production, therefore breakage can happen

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

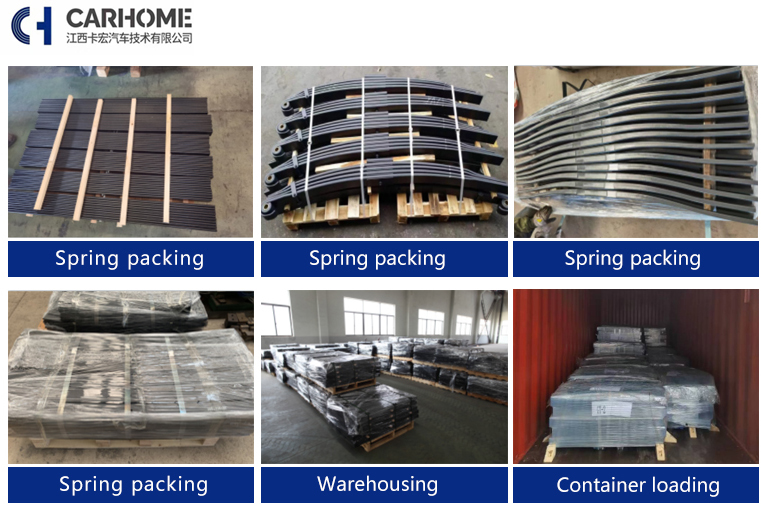

Packing & Shipping

QC equipments

Our advantage

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、Product technical standards:implementation of IATF16949

2、More than 10 spring engineers' support

3、Raw material from the top 3 steel mills

4、Finished products tested by Stiffness Testing Machine, Arc Height Sorting Machine; and Fatigue Testing Machine

5、Processes inspected by Metallographic Microscope, Spectrophotometer, Carbon Furnace, Carbon and Sulfur Combined Analyzer; and Hardness Tester

6、Application of automatic CNC equipment such as Heat Treatment Furnace and Quenching Lines, Tapering Machines, Blanking Cutting Machine; and Robot-assitant production

7、Optimize product mix and reduce customer purchasing cost

8、Provide design support,to design leaf spring according to customer cost

Service aspect

1、Excellent team with rich experience.

2、Think from the perspective of customers, deal with the needs of both sides systematically and professionally, and communicate in a way that customers can understand.

3、7x24 working hours ensure our service systematical, professional, timely and efficient.