Welcome To CARHOME

Auto Spare Parts Heavy Duty Leaf Spring for NISSAN Truck

Product Detail

The leaf spring is suitable for heavy duty

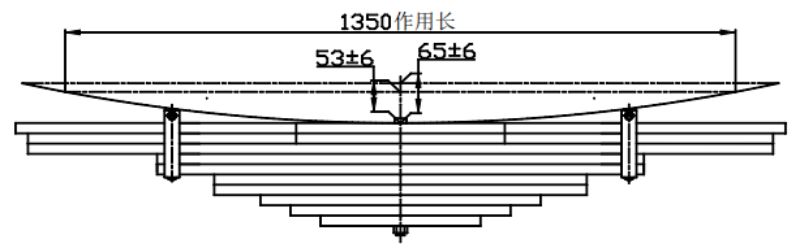

1. The item total has 9 pcs, the raw material size is 90*12 for all leaf

2. Raw material is SUP9

3. The free arch is 120.5±6mm, the development length is 1550, the centre hole is 14.5

4. The painting use electrophoretic painting

5. We also can produce base on client's drawings to design

Leaf springs play a vital role in supporting heavy-duty trucks and trailers by providing suspension and load-bearing capacity.

Their importance lies in their ability to absorb and distribute the weight and impact exerted by the vehicle and its cargo, ensuring a smooth and stable ride.

The leaf spring design consists of multiple layers of spring steel, providing a balance of flexibility and strength to effectively handle heavy loads and withstand the rigors of rugged terrain. Additionally, leaf springs help maintain proper ride height and stability, which reduces rollover risk and enhances overall control, thereby improving overall vehicle safety and handling. Additionally, they help distribute weight evenly on the axles, optimizing the vehicle's load-carrying capacity and ensuring efficient and safe operation. Essentially, leaf springs play an integral role in heavy-duty trucks and trailers, helping to improve their overall performance, durability, and safety. Heavy truck and trailer leaf spring suppliers must prioritize quality materials, advanced manufacturing techniques and continuous product improvements to ensure reliable and durable suspension components that meet the demanding needs of the transportation industry.

Additionally, leaf springs help maintain proper ride height and stability, which reduces rollover risk and enhances overall control, thereby improving overall vehicle safety and handling.

Additionally, they help distribute weight evenly on the axles, optimizing the vehicle's load-carrying capacity and ensuring efficient and safe operation.

Essentially, leaf springs play an integral role in heavy-duty trucks and trailers, helping to improve their overall performance, durability, and safety.

Heavy truck and trailer leaf spring suppliers must prioritize quality materials, advanced manufacturing techniques and continuous product improvements to ensure reliable and durable suspension components that meet the demanding needs of the transportation industry.

Applications

Simply down to the sheer amount of metal layers put together, leaf springs are very absorbent to the weight of your vehicle and the extra weight it will carry.

This offers vital support to the vehicle’s wheels, axels and chassis, absorbing all the extra strain generated by a mix of the weight carried and the external factors such as hard breaks and potholes in the road etc.

Ultimately increasing your vehicles response time and making it much ore controllable in the process.

Driver Comfort

Dependant on the load the vehicle is carrying it is important to match this with the spring the vehicle is fitted with for the sake of comfort and of course safety.

If you are driving a truck with a heavy load for example, heavy duty springs will make the driver feel as though the vehicle is carrying the load, not the other way round.

This level of control will not only ensure peace of mind for you as the driver but reduce the risk of any avoidable accidents.

Do You Need Them?

As previously mentioned, you will only really need this specific type of spring if you frequently carry loads that reach the maximum of your vehicle’s capacity.

It is important to note any haulage to the contrary of this can and will negate any of the benefits these springs can have.

As well as this you will notice a lower acceleration in your vehicle once lightly loaded due to the sheer weight of the springs.

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

Packing

QC equipments

Advantage

Quality aspect:

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

we swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening .

Fatigue test can reach over 150000 cycus

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、Research and development: Investing in R&D enables the factory to continuously improve its products and develop innovative leaf spring designs.

2、Compatibility with international standards: The leaf springs are engineered to comply with global safety and quality regulations.

3、Production capacity: Our factory's large-scale production capabilities ensure a steady supply of leaf springs to meet our customer’ demands.

4、Metal treatment technology: Utilizing heat treatment and surface finishing processes strengthens the leaf springs and protects them from corrosion.

5、Sustainable practices: The factory may prioritize eco-friendly manufacturing methods and materials in line with environmental regulations.

Service aspect

1、Customized solutions: Our factory offers personalized consulting to provide tailored leaf spring designs based on specific customer requirements.

2、Responsive customer support: Efficient communication channels enable timely response to inquiries and technical assistance.

3、Quick turnaround times: Our factory aims to provide fast order processing and delivery to meet urgent customer needs.

4、Product expertise: The factory's team can offer guidance on selecting the right type and configuration of leaf springs for different applications.

5、Warranty and after-sales service: Comprehensive warranties and support services provide peace of mind to customers after purchasing leaf springs.