Before measurement of leaf springs, take photos and keep files, record the product color and material specification (width and thickness), and then measure the dimensional data.

1、Measure the single leaf

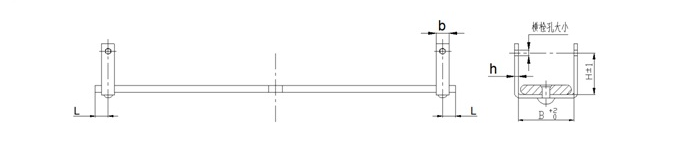

1)Measurement of the clamps and clamp bolts

As shown in below. Measure with a vernier caliper. Record the serial number of the leaf spring sheet where the clamp is located, clamp positioning dimension (L), clamp quantity, material thickness (h) and width (b) of each clamp, clamp bolt hole distance (H), clamp bolt dimension, etc.

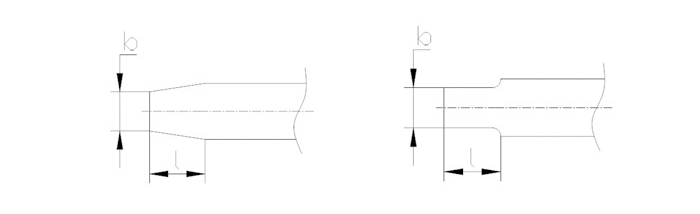

2)Measurement of end cutting and corner cutting

As shown in below. Measure sizes b and l with a vernier caliper. Record the relevant dimensional data (b) and (l).

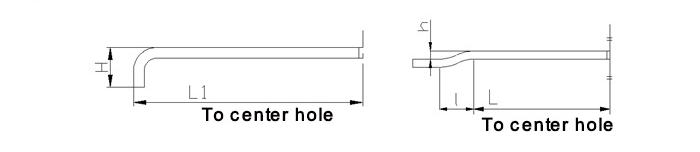

3)Measurement of end bending and compression bending

As shown in below. Measure with a vernier caliper and a tape measure. Record dimensional data (H, L1 or L, l and h.)

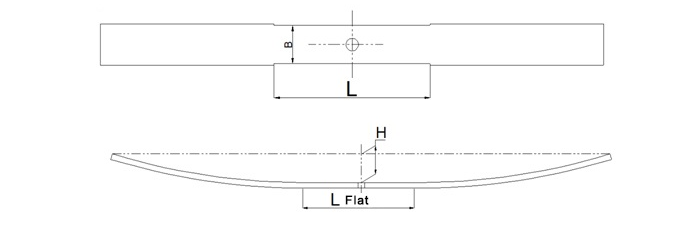

4)Measurement of milling edge and a flat-straight segment

As shown in below. Use a vernier caliper and a tape measure to check and record relevant data.

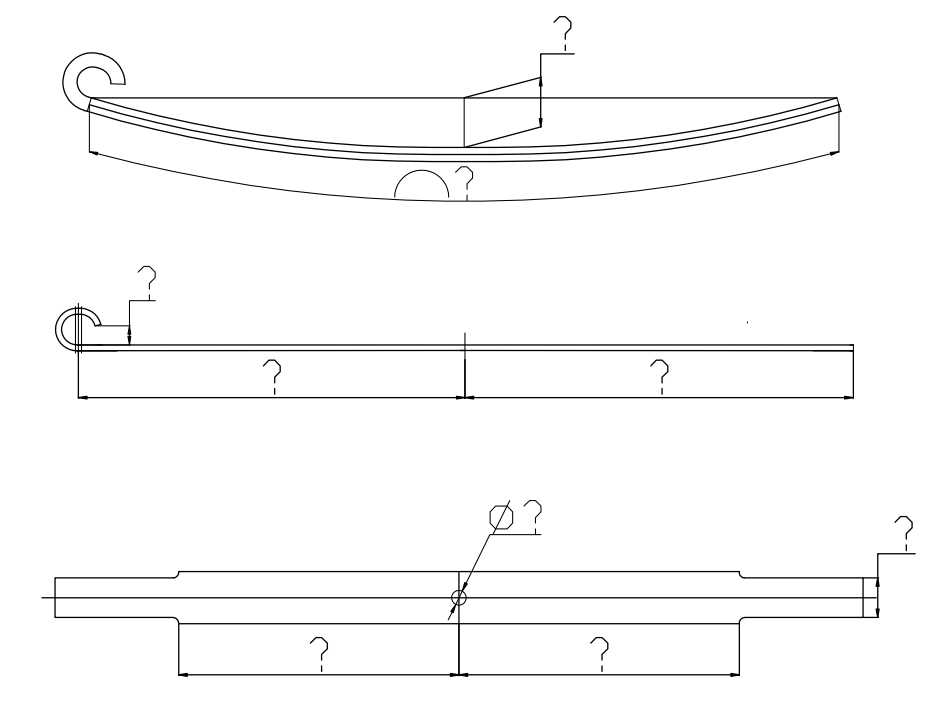

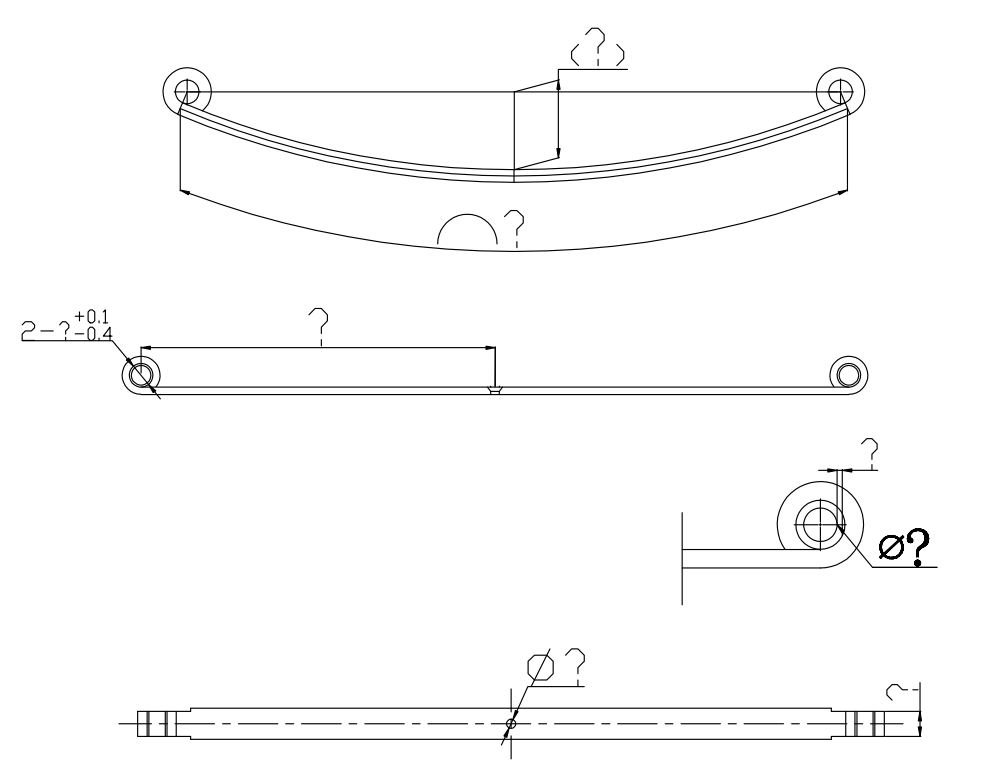

2、Measure the rolled eyes

As shown in below. Measure with a vernier caliper and a tape measure. Record relevant dimensions (?). When measuring the inner diameter of the eye, pay attention to the possibility that there may be horn holes and elliptical holes in the eye. It shall be measured 3-5 times, and the average value of the minimum diameters shall prevail.

3、Measure wrapped eyes of a leaf

As shown in below. Use a cord, a tape measure and a vernier caliper to check (?) and record relevant data.