Step-by-Step Guide to Selecting Heavy-Duty Truck Leaf Springs

Assessing Vehicle Requirements

The first step is to assess your vehicle’s requirements. You should know the specifications and needs of your truck, such as:

The make, model, and year of your truck

The gross vehicle weight rating (GVWR) and gross axle weight rating (GAWR) of your truck

The type and size of the load that your truck carries

The weight distribution of your truck and its cargo

The driving conditions that your truck faces (e.g., smooth roads, rough terrains, hills, curves)

The suspension system design of your truck (e.g., single-leaf spring or multi-leaf spring)

These factors will help you determine the type, size, shape, and strength of the leaf springs that your truck needs.

Researching Spring Options

The next step to selecting leaf springs is to research the available options. You should compare different types and brands of leaf springs, such as:

Parabolic leaf springs: These are leaf springs that have a curved shape and consist of one or more tapered leaves. They are lighter and more flexible than conventional leaf springs, and they offer better ride quality and handling. However, they are also more expensive and less durable than conventional leaf springs.

Conventional leaf springs: These are leaf springs that have a flat or slightly curved shape and consist of several leaves of equal or varying thickness. They are heavier and stiffer than parabolic leaf springs, but they also offer more load-carrying capacity and durability. However, they also have more friction and noise than parabolic leaf springs.

Composite leaf springs: These are leaf springs that are made of a combination of steel and fiberglass or carbon fiber. They are lighter and more corrosion-resistant than steel leaf springs, but they also offer less load-carrying capacity and durability. However, they also have less friction and noise than steel leaf springs.

You should also consider the quality and reputation of the spring manufacturers, as well as the warranty and customer service they offer.

Consulting Experts or Mechanics

The third step to selecting leaf springs is to consult experts or mechanics who have experience and knowledge in leaf spring solutions. You can ask them for advice and recommendations on:

The best type and brand of leaf springs for your truck’s needs

The proper installation and maintenance of leaf springs

The common problems and solutions related to leaf springs

The expected lifespan and performance of leaf springs

You can also read online reviews and testimonials from other customers who have used similar leaf springs for their trucks.

Checking Compatibility

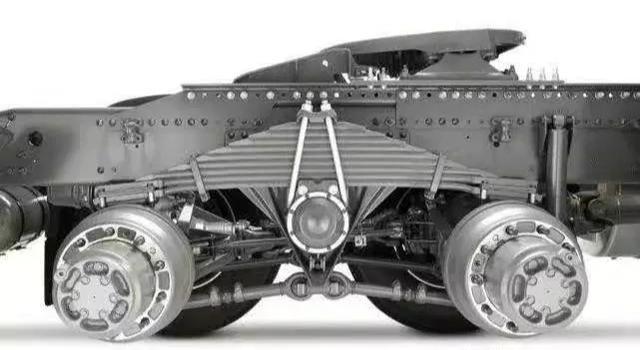

The fourth step to selecting leaf springs is to check the compatibility of the leaf springs with your truck’s suspension system. You should ensure that:

The dimensions and shape of the leaf springs match your truck’s axle size and spring hangers

The spring rate and load capacity of the leaf springs match your truck’s weight rating and load requirements

The attachment points and hardware of the leaf springs fit your truck’s spring shackles, u-bolts, bushings, etc.

The clearance and alignment of the leaf springs allow your truck’s wheels to move freely without rubbing or binding

You can use online tools or catalogs to find compatible leaf springs for your truck’s make, model, and year.

Our company has a history of producing leaf springs for many years. We can give you professional advice based on your sample drawings or needs to help you choose the leaf spring that best matches your truck, and the quality of our company’s leaf springs can be effectively guaranteed. , if you have needs, you can click on our homepage and send us an inquiry, we will reply to you as soon as possible.

Post time: Feb-26-2024