1. Definition:

Cutting: cut spring steel flat bars into the required length according to the process requirements.

1.2.Straightening

Straightening: adjust the side bending and flat bending of the cut flat bar to ensure that the curvature of the side and plane meets the production requirements.

2. Application:

All spring leaves.

3. Operating procedures:

3.1. Raw material inspection

Check the specification, steel grate, heat number, manufacturer and warehousing inspection qualification mark of spring steel flat bar before cutting. All items meet the requirements of leaf spring process, and then transfer to the next process to start cutting.

First piece flat bar shall be cut off for the first inspection. Only it passing the first inspection, it can be submitted to the inspector for review before batch cutting. During batch cutting, it is necessary to prevent the loosening of fixtures from exceeding the tolerance, resulting in repair or scrap.

The cut spring steel flat bar sheets shall be stacked neatly. It is forbidden to place them at will, resulting in surface bruises. The inspection qualification mark shall be made and the work transfer card shall be pasted.

4. Detection Schematic diagram:

After the cutting process, the flat bars need to be detected, mainly including:

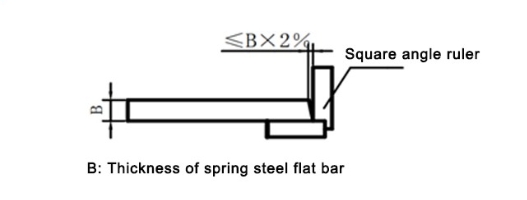

1) Verticality detection of cutting section

As shown in figure 1 below.

(Fig. 1. Schematic diagram of cutting section verticality measurement)

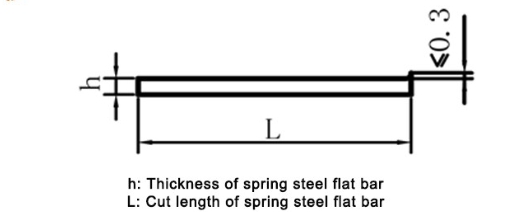

2) Detection of burr height of cutting section

As shown in figure 2 below.

(Fig. 2. Schematic diagram of cutting section burr measurement)

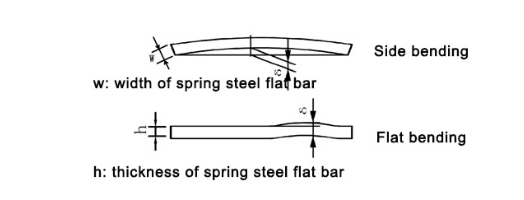

3) Side bending and flat bending detection of cut flat bars

As shown in figure 3 below.

(Figure 3. Schematic diagram of side bending and flat bending measurement of a cut bar)

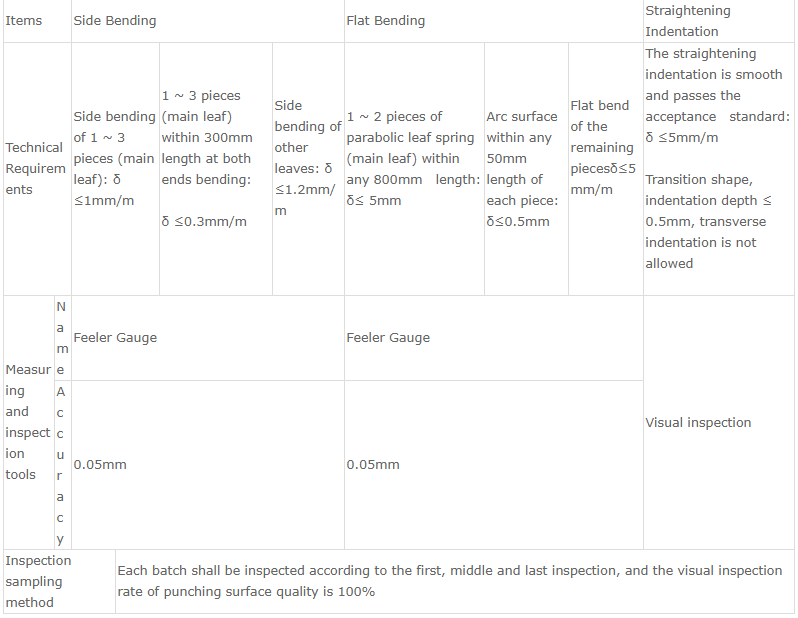

5. Inspection standards:

The inspection standards of spring leaf straightening process as shown in Table 1 below.

If you would like to learn more, please visit www.chleafspring.com at any time.

Post time: Mar-21-2024