Welcome To CARHOME

OEM Foundry Factory Auto Truck Parts Leaf Spring For SCANIA Truck

Detail

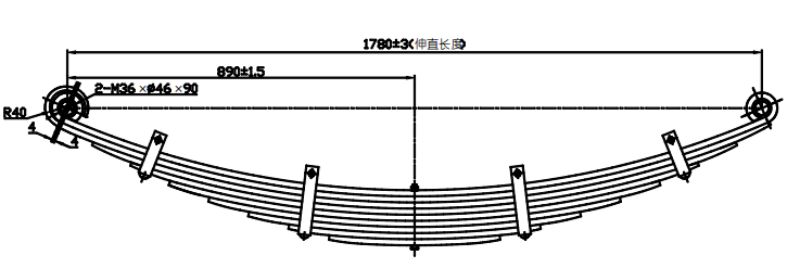

The leaf spring is suitable for SACNIA heavy duty truck and trailer

1. The item total has 9 pcs, the raw material size is 90*15 for all leaf

2. Raw material is SUP9

3. The free arch is 214±5mm, the development length is 1780, the centre hole is 12.5

4. The painting use electrophoretic painting

5. We also can produce base on client's drawings to design

What are the disadvantages of heavy duty leaf springs?

Heavy-duty leaf springs offer many benefits for vehicles that require extra support, stability and load-carrying capacity.

However, they also have certain disadvantages that should be considered before installation.

A significant disadvantage is that vehicle stiffness may increase, which may result in a more difficult ride, especially if the vehicle is not carrying heavy loads.

This can lead to reduced passenger comfort and potential issues with ride quality.

Additionally, heavy-duty leaf springs add extra weight to the vehicle, which can impact fuel efficiency and overall performance.

In addition, the increased stiffness of heavy-duty leaf springs may result in reduced traction on uneven roads, affecting the vehicle's handling and maneuverability.

Another disadvantage is the higher cost of heavy-duty leaf springs compared to standard or lighter alternatives.

Due to their reinforced construction and specialized design, heavy-duty leaf springs tend to be more expensive to purchase and install.

Finally, heavy-duty leaf springs may require more frequent maintenance and inspections to ensure optimal performance, which may result in higher maintenance costs and more inconvenience to the vehicle owner.

So while heavy-duty leaf springs offer many advantages, these potential disadvantages must be carefully considered before deciding to install them on your vehicle.

Applications

The maintaining and servicing about the leaf spring:

When maintaining and servicing leaf springs, regular inspections and proper maintenance are critical to ensuring optimal performance and safety of the vehicle using this suspension component.

Leaf springs play a vital role in supporting vehicle weight and absorbing road shocks, making their maintenance a critical aspect of overall vehicle maintenance.

First, regular visual inspections of leaf springs are critical to identifying any signs of wear, damage, or corrosion. Look for cracks, deformation or any signs of metal fatigue as these can compromise the structural integrity of the leaf spring.

Additionally, it is important to check that leaf springs are properly aligned and installed to prevent uneven wear and potential operating issues.

Additionally, keeping leaf springs properly lubricated is critical to preventing metal-to-metal contact and reducing friction that can lead to premature wear.

Regular use of the appropriate lubricant will help maintain leaf spring flexibility and performance, especially in harsh operating conditions or environments with high humidity and road salt.

When it comes to repairs, any issues discovered during the inspection should be addressed immediately by a qualified technician. This may involve repairing minor damage, replacing worn parts or re-aligning leaf springs as needed.

Additionally, regular maintenance should include tightening U-bolts, ensuring proper torque specifications, and replacing bushings when they show signs of age.

Additionally, given the heavy-duty nature of leaf springs in commercial vehicle and off-road applications, it is recommended that the suspension system undergo periodic load testing and evaluation to verify that the leaf springs are operating within specified parameters.

This helps identify any weakening or loss of load-bearing capacity, allowing for preventive maintenance or timely replacement to avoid potential failure.

In summary, leaf spring care and maintenance is an important aspect of vehicle maintenance and safety.

By performing regular inspections, ensuring proper lubrication, promptly resolving discovered problems, and performing load tests, vehicle owners can extend the life of their leaf springs and minimize the risk of suspension-related problems.

Working with qualified professionals and following the manufacturer's guidelines is critical to ensuring effective leaf spring maintenance and repair.

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

Packing & Shipping

QC equipments

Our advantage

Quality aspect

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、Product technical standards:implementation of IATF16949

2、Raw material from the top 3 steel mills

3、Finished products tested by Stiffness Testing Machine, Arc Height Sorting Machine; and Fatigue Testing Machine. Processes inspected by Metallographic Microscope, Spectrophotometer, Carbon Furnace, Carbon and Sulfur Combined Analyzer; and Hardness Tester

4、Application of automatic CNC equipment such as Heat Treatment Furnace and Quenching Lines, Tapering Machines, Blanking Cutting Machine; and Robot-assitant production

Service aspect

1、Inventory management: Our factory may offer inventory management solutions to ensure availability of leaf springs at all times.

2、Collaborative partnerships: Working closely with clients to understand their needs and provide tailored solutions fosters strong customer relationships.

3、Training and education: Our factory may provide training sessions or educational resources to help customers better understand the use and maintenance of leaf springs.

4、Value-added services: Additional services, such as packaging, labeling, and logistics support, enhance the overall customer experience.

5、Continuous improvement: Our factory is committed to soliciting feedback from customers and refining its services to better meet their evolving needs.