Welcome To CARHOME

OEM Quality Rubber Bush for Heavy Truck and Semi Trailer

Detail

| Product Specifications | ||

| Metal Characteristic | ||

| Metal Material | According To DIN, ASTM, JIS, BS, NF, GB Standard | |

| Surface Treatment | Parkerizing, Polishing, Zinc Plated, Spray Painted | |

| Heat Treatment | Carburizing, Quench Hardening | |

| Tensile Test | Accordance With Industry Standards | |

| Flattening Test | No Crack Until 2/3 * Diameter | |

| Flaring Test | No Crack Until 5/4 * Diameter | |

| Rubber Characteristic | ||

| Rubber Material | NR, EPDM, SBR, NBR, CR, etc | |

| Rubber hardness | 30-90 Shore A | |

| Tensile Strength | 7-25Mpa | |

| Extension Elongation | Custom-made | |

| Compression Set | 35% | |

| Ozone Resistant | Keep Quality 85% min | |

| Temperature Resistant | -45°C | |

| Aging Resistant | Keep Quality 85% | |

| Oil Resistant | Volume Change 10% max | |

| Electric Conduction | Custom-made | |

| Product Characteristic | ||

| Adhesive Strength | Custom-made | |

| Radial Rigidity | Custom-made | |

| Axial Rigidity | Custom-made | |

| Torsional Fatigue | Custom-made | |

| Warranty | 3 Years Or> 50000KM (OEM Grade) 1 Years (Aftermarket) |

|

Applications

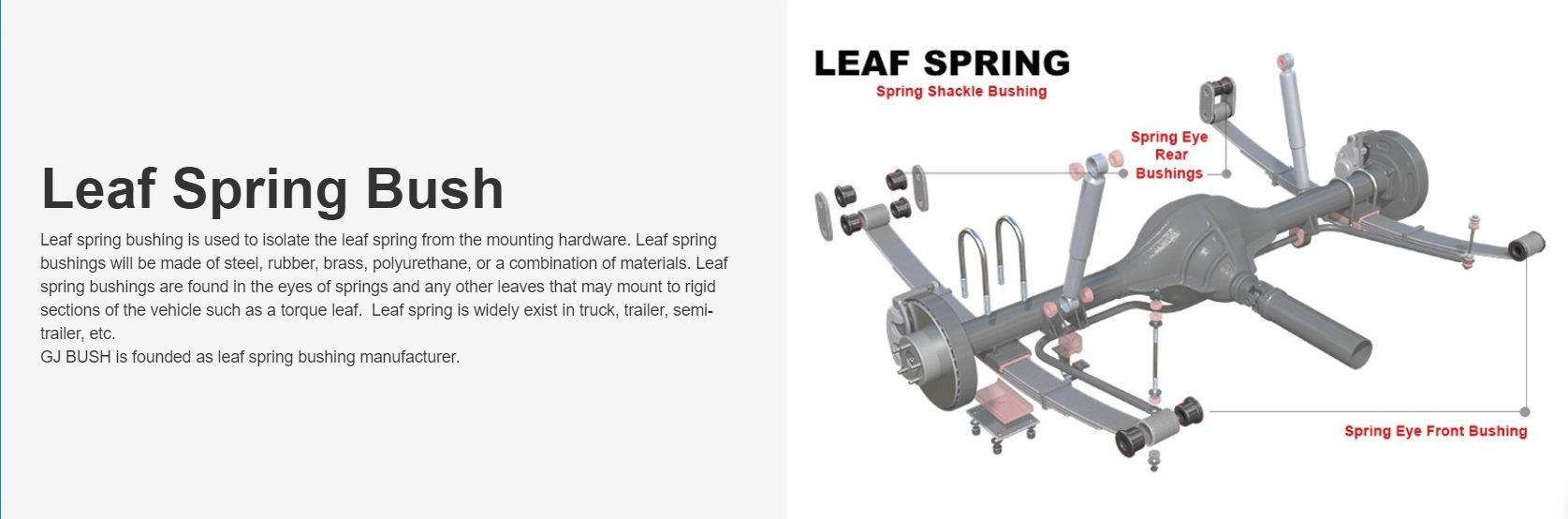

Rubber bushing is used to isolate the leaf spring from the mounting hardware. Leaf spring bushings will be made of steel, rubber, brass, polyurethane, or a combination of materials. Leaf spring bushings are found in the eyes of springs and any other leaves that may mount to rigid sections of the vehicle such as a torque leaf. Leaf spring is widely exist in truck, trailer, semi-trailer, etc. They provide a cushion for all the springs on a vehicle with ones on the front encased in steel while in the rear they are all rubber. Leaf spring equalizer bushings support the ends of leaf springs and allow them to articulate. Because a rubber bushing is designed to operate within a limited range of motion and requires no lubrication, rubber bushings work well in control arm and leaf spring applications. To eliminate wearing surfaces, the rubber bushing is bonded to inner and outer metal sleeves. The outer sleeve is usually pressed into the control arm or spring while the inner sleeve is clamped to the frame by a retainer bolt. Because the rubber bushing absorbs the torsional movement of the suspension component, no frictional or rotational wear takes place. Wear problems occur only when the rubber bushing separates from its inner and outer sleeves. Rubber bushings are also designed to insulate the chassis against road vibration and noise. Ozone, ultraviolet light, extreme temperatures and other atmospheric issues tend to harden rubber bushings and cause them to transmit noise and vibration. Worn suspension bushings can easily be detected by checking the lower and upper control arms for excessive movement when the suspension is disassembled for other repairs. In most cases, the rubber bushings should tend to hold the control arm in position and limit control arm travel. If the control arm can be easily moved beyond its normal range of travel, the rubber bushing has deteriorated or the pivot bolt has loosened and is no longer holding the inner sleeve in position. During a normal vehicle inspection, rubber bushings should be inspected for hardening and stress-related cracking. In many cases, a disintegrating bushing can easily be detected by the blackened ring of rubber particles forming around its circumference when the bushing separates from its metal sleeve. In other cases, the bushing can deform and allow the control arm to move off-center from its normal pivot point. When the bushing deforms, positive camber angle is reduced.

Reference

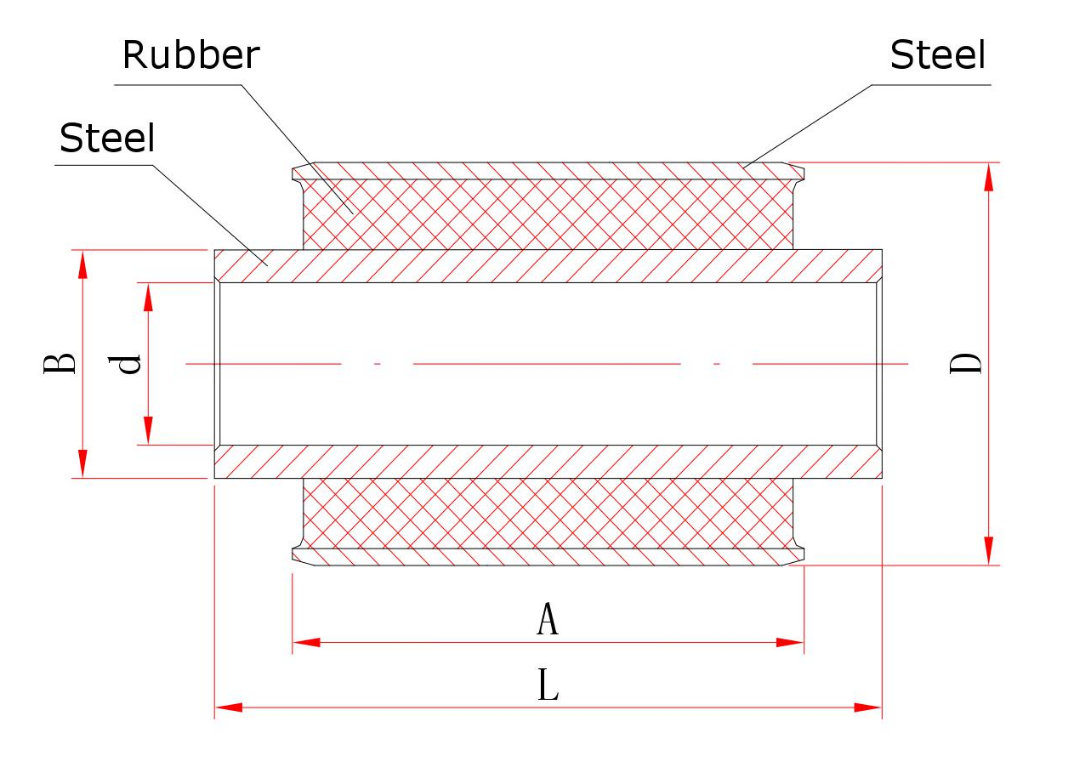

| No. | d | B | D | A | L |

| 1 | 14 | 22 | 40.2 | 32 | 50 |

| 2 | 19 | 25 | 40.2 | 30 | 50 |

| 3 | 12 | 18 | 33.7 | 26 | 32 |

| 4 | 16 | 22 | 40.2 | 28 | 36 |

| 5 | 16 | 22 | 40 | 32 | 40 |

| 6 | 18 | 22 | 34 | 25 | 25 |

| 7 | 25.5 | 43 | 60 | 76 | 82 |

| 8 | 42 | 60 | 78 | 130 | 140 |

| 9 | 6 | 18 | 20 | 16 | 18 |

| 10 | 16 | 20 | 28.7 | 25.5 | 30 |

| 11 | 12.2 | 18 | 32.25 | 26 | 47.9 |

| 12 | 10.2 | 19 | 32 | 26 | 31.6 |

| 13 | 10.1 | 18 | 32.25 | 26 | 31.5 |

| 14 | 12.2 | 24 | 35 | 30 | 51 |

| 15 | 12.5 | 24 | 35 | 30 | 35 |

| 16 | 12.2 | 24 | 35 | 30 | 36 |

| 17 | 12.2 | 24 | 35 | 30 | 47 |

| 18 | 12.2 | 24 | 35 | 30 | 52 |

| 19 | 12.2 | 24 | 35 | 30 | 45 |

| 20 | 14.2 | 24 | 35 | 30 | 40 |

| 21 | 12.2 | 24 | 35 | 30 | 48 |

| 22 | 17.1 | 24 | 35 | 30 | 35 |

| 23 | 17.1 | 24 | 35 | 30 | 38 |

| 24 | 12.2 | 16 | 28 | 30 | 38 |

| 25 | 14.2 | 20 | 35 | 35 | 46 |

| 26 | 14.2 | 23 | 35 | 35 | 43 |

| 27 | 12.2 | 23 | 35 | 35 | 43 |

| 28 | 12.2 | 20 | 35 | 35 | 46 |

| 29 | 12.2 | 20 | 35 | 35 | 43 |

| 30 | 12.2 | 20 | 35 | 35 | 47 |

Packing & Shipping

Our advantage

1.OEM Quality

2.Using high-quality rubber raw materials

3.Strong rust resistance, unaffected by weather and grease

4.1-3 year warranty period for product quality assurance

5.Acceptable custom trademarks

6.Before shipment, 100% quality inspection must be conducted before shipment can be made