Welcome To CARHOME

Semi-Trailer Leaf Spring For BPW, FUWA, HJ, L1 Axle

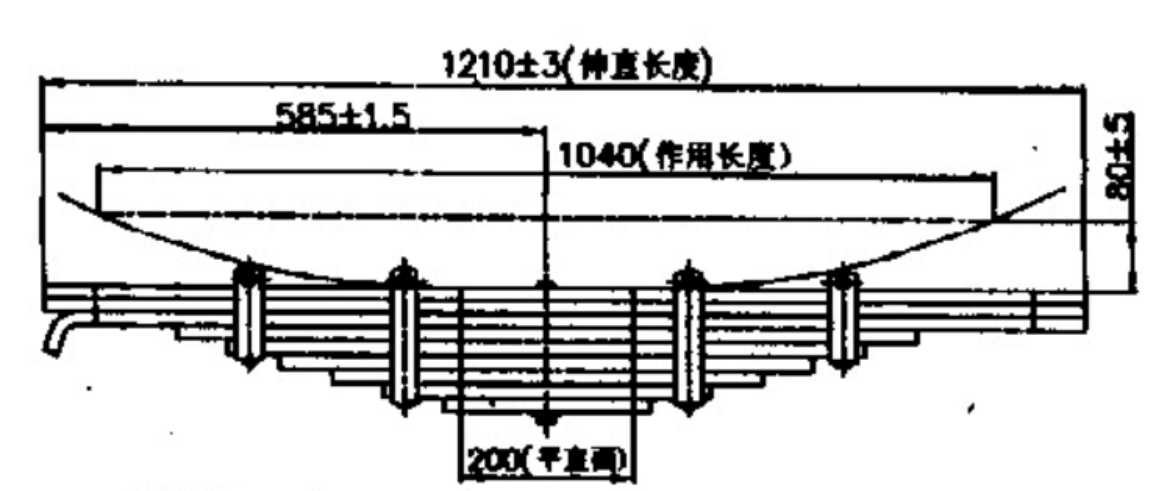

Detail

The leaf spring is suitable for semi-trailer

● The item total has 9 pcs, the raw material size is 76*14 for all leafs

● Raw material is SUP9

● The free arch is 80±5mm, the development length is 1210, the centre hole is 13

● The painting use electrophoretic painting

● We also can produce base on client's drawings to design

Hot selling leaf springs OEM numbers:

| S/N | OEM No. | S/N | OEM No. | S/N | OEM No. |

| 1 | 41310-80010-RA | 21 | 21200078 TA | 41 | 621 320 0002 RA |

| 2 | 55020-Z5106-RA | 22 | 257653 RA | 42 | 48210-2341 |

| 3 | 48210-3V610-RA | 23 | 257654 RA | 43 | 51310-7800-RA |

| 4 | 55020-G6105-RA | 24 | 257847 RA | 44 | 54010-Z3007-FA |

| 5 | 8-97070-508M-RA | 25 | 972015M-TA | 45 | 48110-5570A-FA |

| 6 | MC114890-RA | 26 | 257867 FA | 46 | 101199SC-RA |

| 7 | 48210-87C14-HA | 27 | 48110-87334-FA | 47 | 48120-4340-FA |

| 8 | 8-97070-508M-HA | 28 | TYT 48210-OK020HD | 48 | 1-51340-010-0-HA |

| 9 | HNIT300-FA | 29 | 8-97092-449 FA | 49 | 0178-01-TA |

| 10 | TD50M3-RA | 30 | 48110-3V700-FA | 50 | 54010-Z2006A-FA |

| 11 | 55020-Z2302-RA | 31 | 8-97092-445-1-FA | 51 | 48110-8780A-FA |

| 12 | 55010-C1301-HA | 32 | 8-94118-505-1-HA | 52 | 54011-99117-FA |

| 13 | 48210-5180B-HA | 33 | 8-97073-224-M-HA (5L) | 53 | 48150-2341A-FA |

| 14 | 720612-TA-12.5 | 34 | 97073-225M-HA (9L) | 54 | 48150-2341A-FA-HD |

| 15 | 48220-3360B | 35 | 8-97073-224M-RA | 55 | 55020-Z0073A-RA |

| 16 | 48220-3430A-RA | 36 | 48110-60391W-FA | 56 | 257624M-R1 |

| 17 | CAMC RA | 37 | MB294032-FA | 57 | 54010-01Z17-F3H |

| 18 | 29AD-02010-B FA | 38 | 54010 31Z61-FA | 58 | 54010-NB100-F3 |

| 19 | 0022-RA 2L | 39 | 352-320-1302-FA | 59 | MK306251-R1 |

| 20 | 55022-1T400-RA | 40 | 48110-3V790-FA | 60 | 911B-0508-R1 |

Applications

What's the leaf spring ?

Leaf Spring is one of cells in auto suspension system, the main function is transmitting all force and moments between wheels and car frame, relax impactive load caused by the road surface and realize vehicle guidance, makes vehicles normal drive. It is a necessary component of truck, trailer, special cars and other vehicles.

How do you determine what load capacity you need?

When you bought your truck, you probably had a good idea of what it could do in terms of hauling and towing. However, over time, needs can change and so can the performance of your suspension system. Determining what load capacity you require is a matter of analyzing your applications and seeing how they match up to your current truck specifications. If you have heavy-duty applications that exceed the payload limit, you can upgrade to leaf springs, offering the necessary increase in load capacity.

How can you increase load capacity?

It may come as a surprise that there are not only a variety of ways to increase your truck's capacity for hauling heavy loads but that it's relatively easy and inexpensive. The most common way to give your payload a boost is to upgrade the rear springs with a top-quality OEM replacement or heavy-duty set. Additional ways you can increase your truck's hauling capabilities including adding coil-over shock absorbers or bed racks, attaching a trailer or installing a longer truck bed.

The function of automobile leaf spring:

1. Holding the chassis at ride height

2. Controls the rate at which the chassis rolls

3. Controls the rear end wrap up

4. Controls axle dampening

5. Controls lateral forces such as side load, pan hard, or side bite rate

6. Controls brake dampening forces

7. Sets wheel base lengths during acceleration and deceleration

Reference

Provide different types of leaf springs which include conventional multi leaf springs, parabolic leaf springs, air linkers and sprung drawbars.

In terms of vehicle types, it include heavy duty semi trailer leaf springs, truck leaf springs, light duty trailer leaf springs, buses and agricultural leaf springs.

Production

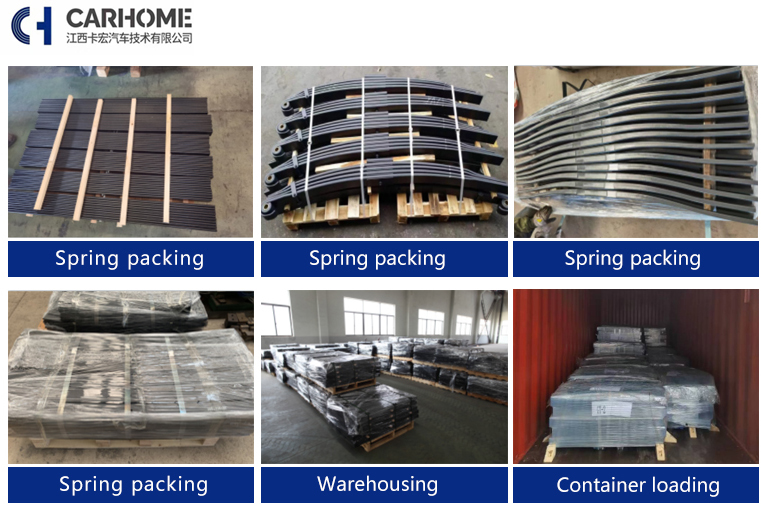

Packing & Shipping

QC equipments

Our advantage

Thickness less than 20mm. We use material SUP9

Thickness from 20-30mm. We use material 50CRVA

Thickness more than 30mm. We use material 51CRV4

Thickness more than 50mm. We choose 52CrMoV4 as the raw material

We strictly controlled the steel temperature around 800 degree.

We swing the spring in the quenching oil among 10 seconds according to the spring thickness.

Each assembling spring set under stress peening.

Fatigue test can reach over 150000 cycles.

Each item use electrophoretic paint

Salt spray testing reach 500 hours

Technical aspect

1、Product technical standards:implementation of IATF16949

2、More than 10 spring engineers' support

3、Raw material from the top 3 steel mills

4、Finished products tested by Stiffness Testing Machine, Arc Height Sorting Machine; and Fatigue Testing Machine

5、Processes inspected by Metallographic Microscope, Spectrophotometer, Carbon Furnace, Carbon and Sulfur Combined Analyzer; and Hardness Tester

6、Application of automatic CNC equipment such as Heat Treatment Furnace and Quenching Lines, Tapering Machines, Blanking Cutting Machine; and Robot-assitant production

7、Optimize product mix and reduce customer purchasing cost

8、Provide design support,to design leaf spring according to customer cost

Service aspect

1、Excellent team with rich experience.

2、Think from the perspective of customers, deal with the needs of both sides systematically and professionally, and communicate in a way that customers can understand.

3、7x24 working hours ensure our service systematical, professional, timely and efficient.